Welcome to our guide on LG window air conditioner error codes. We will discuss common LG window air conditioner error codes, understand their meanings, and learn how to troubleshoot or fix them. If you’ve ever wondered about the meaning of error codes on your LG window A/C, you’re in the right place.

We’ll uncover common error codes, explain their implications, and provide solutions for effective fixes. So, let’s take a look at how to understand and resolve these error codes effectively.

Most Common LG Window Air Conditioner Error Codes: Troubleshooting Made Easy

Always exercise caution when working with electronic components.

CH 01: Room Air Temperature Sensor Error (Same as E2 Error)

The CH 01, E2 error code is displayed on your LG window air conditioner when the appliance detects an open or shorted room air temperature sensor. This issue can lead to incorrect temperature readings and compromised performance.

Possible causes include a disconnected sensor, damaged sensor harness, faulty sensor, or a defective main board.

Solutions:

- Inspect the sensor harness for any signs of damage or breaks.

- Ensure a secure connection of the sensor to the main board.

- Check for any moisture accumulation around the sensor connector.

- Verify the ohm reading of the sensor. The resistance should measure 10 kiloohms at 25°C (77°F).

- If the sensor passes the resistance test and no connection or wiring problems are detected, consider replacing the PCB to which the sensor is connected. This step may resolve the issue if the problem originates from the control board.

CH 02: Evap. Pipe Temperature Sensor Error (Same as E1 Error)

The “CH 02, E1 Evaporator Pipe Temperature Sensor Error” on your LG window air conditioner indicates that the appliance has identified an issue with the pipe temperature sensor. This error usually occurs when the sensor is either open (disconnected) or shorted.

Possible causes for this error include:

- The sensor has become disconnected.

- The sensor’s harness might be damaged.

- There could be a problem with the sensor itself.

- A malfunction in the main control board might also trigger this error.

Solutions:

- Examine the sensor’s wiring harness for any visible signs of damage or breaks. Ensure that the wires are properly connected and not severed.

- Verify that the sensor is securely connected to the main control board. Make sure the connection is snug and not loose.

- Look for any moisture or water around the sensor connector. Moisture can cause electrical issues and affect sensor readings.

- Measure the resistance of the sensor using an ohmmeter. At a temperature of 25°C (77°F), the sensor’s resistance should read around 5 kilo ohms. If the sensor’s resistance reading is far from 5 kiloohms, consider replacing the sensor with a new one.

- If the sensor tests correctly and there are no apparent issues with connections or wiring, the problem might lie with the PCB.

CH 03: Outdoor Air Temperature Sensor Error

The “CH 03 Outdoor Air Temperature Sensor Error” on an LG window air conditioner indicates that the appliance has identified an issue with the outdoor air temperature sensor.

This error usually occurs due to reasons like a disconnected sensor, damaged sensor harness, a faulty sensor itself, or even a malfunctioning main board within the unit.

Solutions:

- Inspect the sensor harness for damage or breaks.

- Check the connection of the sensor to the main board.

- Look for moisture around the sensor connector; clean and dry it if necessary.

- Measure the ohm reading of the sensor. The resistance should be around 10 kilo ohms at 25°C (77°F).

- If the sensor tests correctly and there are no connection or wiring issues found, consider replacing the PCB that the sensor is connected to.

CH 04: Outdoor Pipe Temperature Sensor Error

The “CH 04 Outdoor Pipe Temperature Sensor Error” on an LG window air conditioner indicates that the appliance has detected a problem with the outdoor pipe temperature sensor.

This error can be triggered by issues such as a disconnected sensor, damage to the sensor harness, a malfunctioning sensor, or even a faulty main board within the unit.

Solutions:

- Inspect the sensor harness for any signs of damage.

- Check the connection of the sensor to the main board.

- Examine the sensor connector for moisture; ensure it’s clean and dry.

- Measure the ohm reading of the sensor. The resistance should be approximately 4 kiloohms at 30°C (86°F).

- If the sensor tests correctly and there are no issues with connections or wiring, you might need to replace the PCB that the sensor is connected to.

CH 05: Communication Error (Same as CH 53, CH 93, and EA Error)

The “CH 05, CH 53, CH 93 Communication Error” on an LG window air conditioner indicates a problem with the communication signal between the main board and the display board.

This error can arise due to issues such as supply voltage problems, wiring problems between the Main Board and Display Board, or even a faulty Main/Display Board.

Solutions:

- Ensure that the supply voltage provided to the unit falls within the correct range.

- Confirm that the wiring harness is fully and securely connected to both the main control board and the display board.

- Thoroughly examine the wiring harness for any signs of breaks, frays, or pinched wires. Damaged wiring can cause communication issues and trigger errors.

- If you identify any issues with the wiring harness, such as breaks or pinched wires, it’s recommended to replace the damaged wiring harness with a new one.

- Disconnect and then reconnect the connectors to both the main control board and the display board. Sometimes, reseating connectors can help establish a better connection.

- If reseating connectors and addressing voltage and harness issues do not resolve the error code:

- Replace the main and display boards together. If no supply voltage or harness issues are detected and reseating connectors doesn’t resolve the error.

CH 09: EEPROM Error (Same as CH 60 Error)

The “CH 09, CH 60 EEPROM Error” on an LG window air conditioner points to a corrupted EEPROM, which is a memory chip storing important data.

This error can occur due to supply voltage problems or a faulty PCB.

Solutions:

- Verify that the supply voltage provided to the unit falls within the correct range.

- If the supply voltage is correct but the error persists, try disconnecting power to the unit for approximately 10 minutes. This will allow the system to reset and potentially clear any temporary issues.

- If the error persists after a reset:

- If the error code reappears even after the power reset and the supply voltage is confirmed to be within the correct range, the next step is to consider replacing the main board.

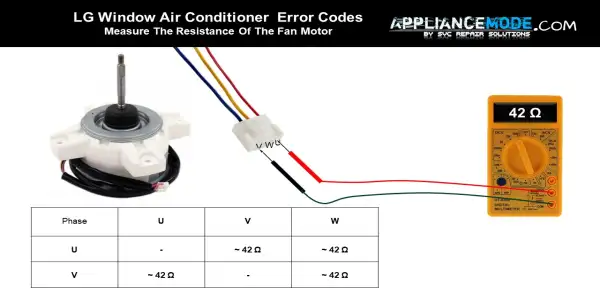

CH 10: Fan Motor Error (Same as CH 67 Error)

The “CH 10, CH 67 Fan Motor Error” on an LG window air conditioner indicates that the appliance is unable to receive a valid signal value from the fan motor.

This error can be caused by issues such as disconnected fan wires, damaged fan harness, a faulty fan motor, or even a malfunctioning main board.

Solutions:

- Attempt to turn the fan blade by hand. If it doesn’t move, inspect the area around the fan for any obstructions that might prevent it from turning freely.

- Examine the fan blade itself for any damage or deformation. A damaged blade might not function properly, leading to errors.

- Thoroughly inspect the fan’s wiring harness for any signs of damage or wear. Damaged wiring can disrupt the signal transmission and operation of the fan.

- Verify that the fan is securely connected to the main control board. Ensure the connection is tight and not loose.

- Test the fan motor’s resistance using an ohmmeter. Measure the resistance across various wire combinations (yellow-blue, yellow-red, and red-blue). The resistance should fall within the range of 42 to 56 ohms at an ambient temperature of 25°C (77°F).

- If the fan tests correctly and all other components are in good condition, the issue might lie within the main control board. In this case, consider replacing the main control board to solve the issue.

CH 21: Compressor Overcurrent Error (Same as CH 22 Error, CH 26 Error, and CH 29 Error)

The “CH 21, CH 22, CH 26, CH 29 Compressor Overcurrent Error” on an LG window air conditioner indicates that the appliance has detected an excessive current draw in the compressor.

This error can be triggered by various factors including supply voltage issues, airflow restriction, a faulty fan, refrigerant leaks, a defective compressor, or even a malfunctioning main board.

Solutions:

- Attempt to turn the fan blade by hand. If it’s not turning, look for obstructions around the fan that might be preventing it from moving.

- Examine the fan blade for any damage or deformities. A damaged blade can affect the unit’s function.

- Inspect the fan’s wiring harness for any signs of damage or wear that might affect its connectivity.

- Ensure that the fan is properly connected to the main control board. Confirm that the connection is secure.

- Test the fan motor’s resistance using an ohmmeter. Measure resistance across different wire combinations (yellow-blue, yellow-red, and red-blue). Resistance should be between 42 and 56 ohms.

- Regularly clean the condenser coils to ensure efficient heat exchange and prevent cooling issues.

- Confirm that the A/C’s climatic class is suitable for the ambient temperature. This ensures optimal performance.

- Test the compressor’s resistance. Any combination of blue, red, or yellow should provide the same value. The ohm reading should be between 1.3 and 1.6 ohms.

- Visually examine the A/C for signs of oil that could indicate a refrigerant leak.

- Repair and/or replace leaking parts if necessary.

CH 23: DC Link Voltage: High or Low Error

The “CH 23 DC Link Voltage High/Low Error” on an LG window air conditioner happens when the appliance detects irregularities in the DC link voltage.

This error can be triggered by supply voltage issues, a defective wire harness, or a faulty main board.

Solutions:

- If you find supply voltage issues, address the voltage problem to ensure the unit operates within the correct parameters.

- If the wiring harness is not properly connected or shows signs of damage, replace the wiring harness to ensure reliable communication.

- If reseating connectors and addressing voltage and harness issues do not resolve the error, consider replacing the main board.

CH 24: High Pressure Switch Error (Same as CH 34 Error and CH 43 Error)

The “CH 24, CH 34, CH 43 High Pressure Switch Error” on an LG window air conditioner occurs when the appliance detects an open circuit in the high-pressure switch.

This error can be caused by issues such as unit overheating, restricted airflow, or a faulty high-pressure switch

Solutions:

- Inspect the area around the fan for any obstructions that might be causing reduced airflow.

- Examine the condenser coil for dirt, dust, or debris accumulation. A dirty coil can impede heat transfer and overall system performance.

- Confirm that the LG A/C unit has been correctly installed, including considering the appropriate climate class for the installation environment.

- Test the pressure switch’s resistance using an ohmmeter. The resistance value should be less than 1 ohm. If the pressure switch is faulty, the resistance value might show as OL (open loop).

CH 36: Refrigerant Leakage Error (Same as CH 38, E3 Error)

The “CH 36, CH 38 Refrigerant Leakage Error” on an LG window air conditioner is triggered when the evaporator pipe temperature sensor detects a lower value than expected.

This error can result from a faulty sensor or a refrigerant (freon) leak.

Solutions:

- Identify the source of the refrigerant leak. Inspect the system components, including coils, tubing, connections, and valves, for signs of oil, corrosion, or visual damage.

- Depending on the location and severity of the leak, repair or replace the affected parts. This might involve brazing or using appropriate sealants to seal the leak.

- Once the leak is repaired, use a vacuum pump to evacuate any air and moisture from the system. This step ensures the system is properly prepared for refrigerant recharging.

- Refill the system with the appropriate type and amount of refrigerant specified for your air conditioning unit. Follow manufacturer guidelines and ensure accurate charging.

CH 41: Discharge Pipe Sensor Error

The “CH 41 Discharge Pipe Sensor Error” on an LG window air conditioner indicates that the appliance has identified an open or shorted sensor in the discharge pipe.

This error can be caused by problems such as faulty wiring, a defective sensor, or a malfunctioning main board.

Solutions:

- Examine the sensor’s harness for any visible signs of damage or wear.

- Ensure the sensor is properly connected to the main control board. Confirm that the connection is secure and not lost.

- Look for any moisture or water around the sensor connector. Moisture can lead to electrical problems and inaccurate readings.

- Use an ohmmeter to measure the sensor’s resistance. At a temperature of 20°C (68°F), the resistance should read around 244 kiloohms.

- If the sensor tests correctly and all other components are in good condition, the issue might lie within the main control board. In this case, consider replacing the main control board that the sensor is connected to.

E4: Defrost Mode Notification

The E4 notification is not an error code but rather a signal that your air conditioner has activated defrost mode.

Conclusion:

Understanding and addressing LG window air conditioner error codes like CH 01 and CH 02 is essential for maintaining optimal cooling performance. By identifying the root causes, such as sensor disconnects, harness damage, faulty sensors, or main board issues, you can take effective steps to resolve these errors and ensure your air conditioner operates seamlessly.

FAQs: LG Window Air Conditioner

I am a master Appliance Repair technician with over 35 years of experience in the field. I am passionate about helping people troubleshoot their appliances and fix common problems. My website, appliancemode.com, provides a wealth of information on troubleshooting common appliance issues and deciphering error codes. This website aims to empower people to tackle appliance repairs themselves and save money on service calls.

10,000btu lg window ac thinQ , with error CH 41 , how bad is that error thanks for information