If you are looking to buy a new compressor for your refrigerator, whether for commercial or domestic applications, it’s important to choose the right one to ensure your sealed system functions effectively and efficiently. But with so many options available, how do you know which one to pick?

One helpful tip is to learn how to read the compressor label. This label is like an ID card that tells you important details about the compressor, such as its application, freon type, voltage input, cooling capacity, and more. By understanding what’s on the compressor label, you can easily find the right compressor for your needs and even find alternative models if necessary.

In this blog post, we’ll guide you through the process of interpreting compressor labels, enabling you to select the right compressor for your needs and find alternative options if your preferred model is unavailable.

Selecting the Perfect Compressor for Your Refrigeration System:

Key Specifications to Consider When Selecting a Compressor for Your Refrigerator

When choosing a compressor, there are a number of specifications that should be taken into consideration, including:

- The cooling capacity, which is typically measured in watts, Kcal/h, or Btu/h

- The type of refrigerant that the compressor is designed to use

- The voltage and frequency

- The type of compressor, such as whether it is a conventional “on/off fixed speed” or inverter model “variable speed,”

- The specific application requirements for the compressor, such as whether it is intended for use in low, medium, or high back pressure systems (LBP, MBP, and HBP),

- Electrical connections

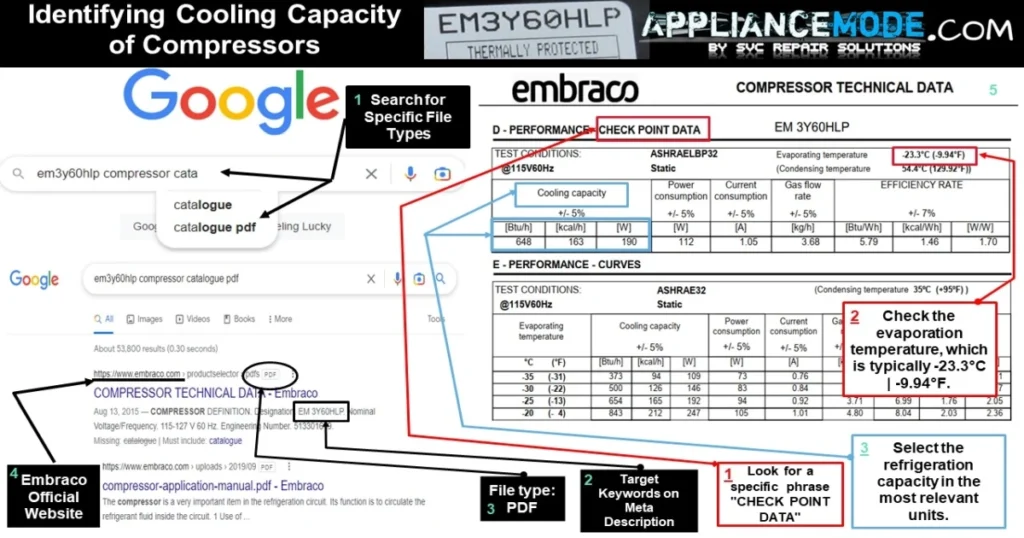

How to obtain compressor specifications: guidance for technicians

To obtain this information, there are a few methods you can use:

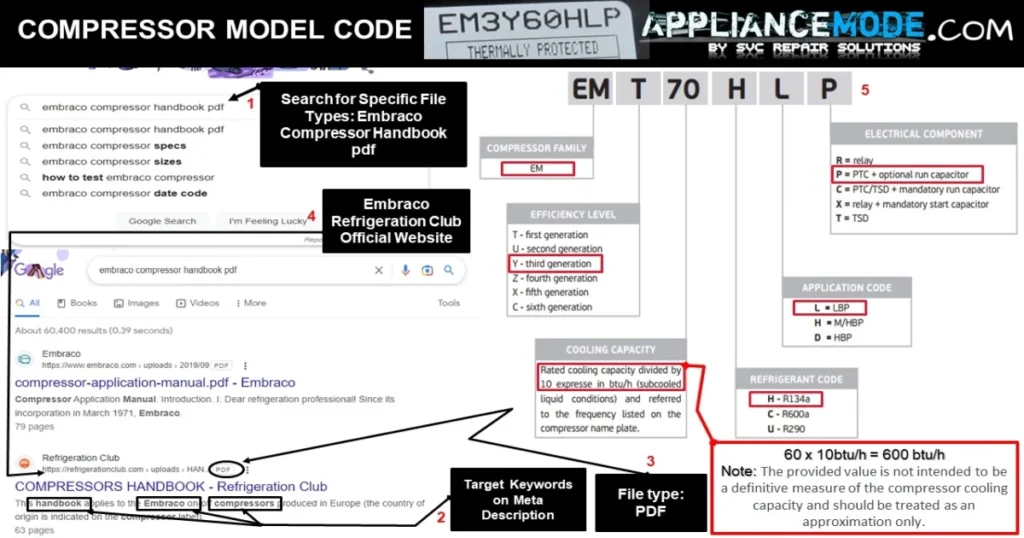

- Conduct a search on Google.com, which is the recommended option.

- Visit the website of the compressor manufacturer to look for the necessary specifications. However, since some technicians may not be familiar with the official website of the compressor company, it is best to rely on the first option and conduct a Google search.

Understanding Compressor Labels: Reading and Interpreting Specifications

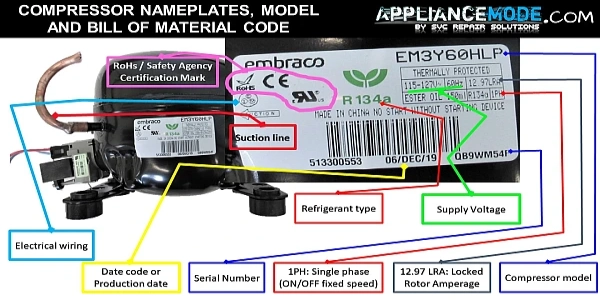

Let’s take a look at how we can read the compressor label to find out its specifications. We’ll use the Embraco EM3Y60HLP compressor as an example. The label provides us with the following information:

- The manufacturer’s logo

- The model number, which we can use to access its data,

- The input voltage

- The type of freon that the compressor will work with

- There is also an arrow indicating where to position the section. It is important to position the suction line correctly; otherwise, the efficiency of the compressor could drop by 6–8 percent

- The label also shows the date of production of the compressor

- Additional information, including electrical safety labels, may be necessary for the compressor to be approved for sale in certain markets

It’s important to pay attention to the label and the information it contains. This can help you pick the right model for your needs and prevent any problems with your refrigeration system. The label will tell you important details like the compressor’s model number, voltage, frequency, number of phases, type of refrigerant used, and current when the rotor is locked.

Overall, just be sure to carefully read and understand the information on the compressor label to make an informed decision and avoid any potential issues down the line.

Once we have obtained this data, we can use it to determine the specifications of the compressor.

Discovering details about the compressor by reviewing its model number

The compressor model number nomenclature provides further information on the compressor model, such as family, generation of technology, mechanical kit type, capacity, freon used, efficiency level, application, starter device used, and start torque. The EM3Y60HLP compressor model is given as an example of how to understand this information.

Compressor Range Explained:

1. Application description:

| Compressor Application | Description |

|---|---|

| LBP | Refrigeration models designed for low evaporating temperatures are ideal for applications that require a working evaporating temperature below -20°C. These models are perfect for use in refrigerators (top mount, side by side, FDBM, etc.), chest freezers, frozen food cabinets, upright freezers, frozen food display cases, and similar applications. |

| L/MBP | If you need a refrigeration model for applications with a working evaporating temperature between -35°C and 0°C, consider using L/MBP (low/medium evaporating temperature) models. These models are ideal for use in refrigerators (top mount, side by side, FDBM, etc.), ice cream freezers, bottle coolers, chest freezers, professional kitchen coolers, and other similar applications. |

| MBP | Medium evaporating temperature models are designed for applications with working evaporating temperatures higher than -20°C. These models are perfect for use in drink dispensers, bottle coolers, fresh food cabinets, and ice makers, among other similar applications. |

| HBP | High evaporating temperature models are designed for applications with working evaporating temperatures higher than -15°C. These models are ideal for use in dehumidifiers, dryers, drink coolers, ice makers, and fresh food cabinets, among other similar applications. |

2. Starting torque classification:

| Starting torque | Meaning |

|---|---|

| LST | Low-starting torque compressors |

| HST | high-starting torque compressors. |

3. Electrical motor types:

| Electrical motor types | Meaning |

|---|---|

| RSIR | Resistance Start Inductive Run |

| CSIR | Capacitive Start Inductive Run |

| RSCR | Resistance Start Capacitive Run |

| PSC | Permanent Split Capacitor |

| CSR | CSCR | Capacitive Start and Run | Capacitor Start, Capacitor Run |

Identifying the Cooling Capacity of Compressors by Using the ASHRAE System

Determining the cooling capacity of a compressor is super important! One way to do this is by running the compressor under specific conditions. When figuring out the cooling capacity, it’s essential to consider the evaporation temperature, which can change depending on the application.

Now, there are different test systems available, but we’re going to focus on the ASHRAE system, which is the most widely used in many countries around the world and has different evaporation temperature application systems for low back pressure (LBP) and medium/high back pressure (MBP/HBP) applications.

For LBP applications, the ASHRAE system uses an evaporating temperature of -23.3°C | -9.94°F, and for MBP/HBP applications, it uses +7.2°C | +44.96°F. It’s essential to know the evaporation temperature to figure out the cooling capacity of the compressor for a specific application. So, keep that in mind!

Compressor Cooling Capacity Conversion Formula

If a unit of cooling capacity is not listed in the catalog, it may be necessary to perform conversions using one of the several equations listed below, depending on your specific requirements or market conditions.

| Unit | Equation |

|---|---|

| Kcal/h to Watt | W = 1.163 x kcal/h |

| Watt to Kcal/h | Kcal/h = 0.86 x W |

| Btu/h to Watt | W = 0.2928 x btu/h |

| Watt to Btu/h | Btu/h = 3.414 x W |

| Kcal/h to Btu/h | Btu/h = 3.96832 x kcal/h |

| Btu/h to Kcal/h | kcal/h = 0.252 x Btu/h |

| Ton of refrigeration to Btu/h | Btu/h = TR x 12000 |

| Btu/h to Ton of refrigeration | TR = btu/h / 12000 |

| Ton of refrigeration to Watt | W = TR x 3516.8 |

| Watts to Ton of refrigeration | TR = W / 3516.8 |

| Watt to HP | HP = Watt / 746 (Not recommended) |

Example:

1. In a hypothetical scenario, let’s assume that the compressor’s catalog only contains btu/h units, while the market works with watts. A conversion formula is necessary. Multiply the btu/h value by the conversion factor of 1 btu/h = 0.2928 watts to convert it to watts. This ensures that values in the catalog are easily understood and comparable in the market.

- Btu/h to Watt | Watt = 0.2928 x btu/h

Watt = 0.2928 x 648 = 189.7344

648 btu/h = ~ 190 W

2. To obtain the kcal/h value from watts, we use the following equation:

- Watt to Kcal/h | Kcal/h = 0.86 x W

Kcal/h = 0.86 x 190 = 163.4

190 W = ~ 163 kcal/h

Tips for Finding a Suitable Replacement Compressor

If you need to replace your compressor, it’s best to look for one that meets the same standards as your old one. You might not find an exact match, but you can choose a compressor that has a similar cooling capacity for the same application. By reading this guide carefully, you can learn how to find comparable compressors in your area, evaluate them, and choose the best one for your needs. Even though it might be tough to find the compressor you want, with practice, you’ll get better at searching online and finding what you need quickly.

Conclusion:

Choosing the right compressor for your commercial refrigerator or home appliance is essential for ensuring optimal performance and longevity. By learning how to read the compressor label, you can gain valuable insights into the freon type, application, and refrigeration capacity of the compressor, which will help you make an informed decision when it comes to selecting the right model.

Discover more about basic knowledge. Learn more today.

Catalog References:

I am a master Appliance Repair technician with over 35 years of experience in the field. I am passionate about helping people troubleshoot their appliances and fix common problems. My website, appliancemode.com, provides a wealth of information on troubleshooting common appliance issues and deciphering error codes. This website aims to empower people to tackle appliance repairs themselves and save money on service calls.