If you’re facing issues with your LG refrigerator’s linear compressor, such as it not turning on or showing unusual resistance readings, this blog post will help guide you through troubleshooting the LG linear compressor process. Specifically, we will explore how to test your LG FMA102NBMA compressor and identify the potential causes behind the malfunction.

Troubleshooting the LG Linear Compressor: Common Problem

One of the most common issues with LG refrigerators, particularly those using the linear compressor, is when the compressor fails to start. If you’ve noticed that your refrigerator isn’t cooling properly, it could be due to a malfunctioning compressor. Let’s break down the steps to help you identify the issue.

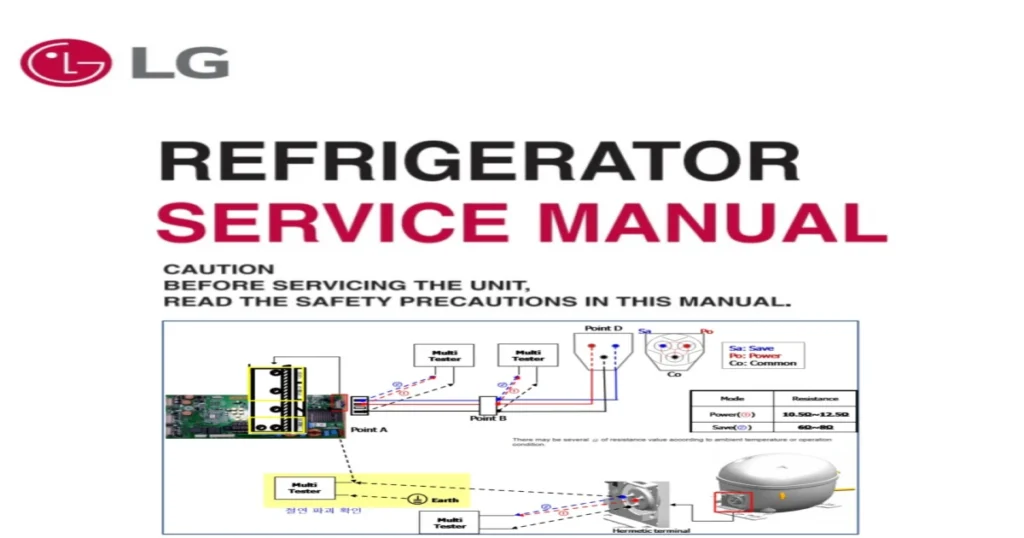

Step 1: Checking Resistance Across the Compressor Pins

The first step in diagnosing a compressor issue is to check the resistance across the compressor pins. For the LG linear compressor, this typically involves measuring the resistance between the three compressor terminals (Common, Power, and Save). In one instance, a user reported measuring 0 ohms between two of the pins and 16 ohms between the third. Generally, for a healthy compressor, you should expect a reading between 5.1 and 6.3 ohms across the common and power pins. A resistance of 16 ohms may indicate a malfunction, but this isn’t always definitive. It’s important to cross-check the readings with your refrigerator’s specific service manual, as some models may have slightly different expected values.

Step 2: Check for Control Issues

If the resistance seems normal but the compressor still doesn’t run, the problem could be with the control board, thermistors, or other components in the control circuit. The LED status on your refrigerator’s PCB (Printed Circuit Board) may offer useful clues. For example, if you notice a three-flash error code, it could indicate that the board is detecting a failure to start the compressor, suggesting a compressor malfunction.

Before replacing the compressor, it’s advisable to check the following:

- PCB and Control Board: Ensure the control board is functioning properly by checking for visible damage, burnt components, or loose connections.

- Thermistors: These sensors are responsible for regulating temperature and could cause issues if they fail.

- Inverter: LG refrigerators with linear compressors rely on an inverter to manage voltage. Ensure that you’re receiving the correct power signal (80V to 230V AC).

Step 3: Check Power Supply to the Compressor

Once you’ve ruled out control board issues, check whether power is actually reaching the compressor. You can do this by measuring the voltage at the compressor’s terminal connections. Typically, LG refrigerators with linear compressors operate using high-voltage AC (ranging from 80V to 230V), so if you are unsure about handling high voltage, it’s best to seek professional help.

Step 4: Inspect the Start Relay

Although LG linear compressors don’t use a traditional start device or relay like other models, it’s important to verify that there’s no issue with the compressor’s internal electronics or inverter

Step 5: Replacing the Compressor

In some cases, after exhausting all troubleshooting steps, the compressor itself may need to be replaced. Symptoms such as irregular resistance readings (like the 21 ohms), consistent 3-flash LED codes, or a total lack of response from the compressor could point to internal failure.

While replacing the compressor may seem daunting, it is sometimes the most cost-effective solution. However, before making this step, make sure all other components (inverter, control board, etc.) have been thoroughly inspected. Additionally, ensure the new compressor is compatible with your specific refrigerator model.

Conclusion

Diagnosing compressor problems in an LG refrigerator with a linear compressor requires methodical testing and attention to detail. From measuring resistance at the compressor terminals to checking the control circuit and ensuring proper voltage levels, following these troubleshooting steps will help you identify the issue with greater confidence.

However, if you’re unsure or uncomfortable working with high-voltage components, it’s always recommended to call a professional technician. Replacing the compressor or repairing the control circuit may require specific skills and tools to ensure the job is done safely and correctly.If you’re still facing difficulties or have additional questions, feel free to share your experience in the comments section below.

I am a master Appliance Repair technician with over 35 years of experience in the field. I am passionate about helping people troubleshoot their appliances and fix common problems. My website, appliancemode.com, provides a wealth of information on troubleshooting common appliance issues and deciphering error codes. This website aims to empower people to tackle appliance repairs themselves and save money on service calls.

My reading between two prongs is 11 ohms. Is my compressor bad?

Your reading of 11 ohms between two prongs on your compressor doesn’t immediately tell us if it’s bad.

This guide, LG Inverter Refrigerator LED Blinking Error Codes (https://appliancemode.com/lg-inverter-refrigerator-led-blinking-error-codes/), is indeed a great resource if you have an LG inverter refrigerator and are seeing error codes. While it might not directly give you the ohm specifications for your compressor, it could help diagnose other issues that might seem like a bad compressor but are actually related to the inverter board or other components.